Proto owner named Washington’s small-business person of the year

Rory Lee Nay presides over a wood shop, machine shop, paint shop and urethane shop – each a separate operation within Proto Technologies Inc. of Liberty Lake.

She does it so well the U.S. Small Business Administration earlier this month named her Washington State Small Business Person of the Year.

Proto, as the name suggests, specializes in making prototypes of new products or product components. But Nay said the company’s 27 employees also make small production runs of pieces it would make no sense for the customer to gear up for.

Last year, sales reached $3 million, she said.

Although work has slowed slightly, she said, all but two of the most recent hires were retained.

Nay said requests for quotes on larger jobs have picked up, signaling a pickup in future orders.

When the economy turns, she said, “Everybody’s going to be busy because the shelves are empty.”

SBA Seattle District Director Nancy Porzio recognized Nay’s willingness to make the tough business and financial decisions that will position Proto for growth.

“Rory responds to adversity as a springboard for new product development,” Porzio said.

Nay said manufacturers have been keeping a tight hold on inventories while they prepare next-generation products. Because technology progresses so rapidly, they must develop and prototype new designs constantly or they will lose their market to imports, she said.

Sometimes, Nay said, Proto turns around an order before a customer decides to revise the design.

Even though the company has one customer as far away as France, she said its two sales representatives constantly fight the perception Proto is too far away, even from the Puget Sound area.

Nay said Proto snagged one new customer by putting a finished prototype on his desk 19 hours after the design was transmitted over the Internet, beating a Seattle supplier’s turnaround time.

The company has customers in the aerospace, automotive, medical and other industries, she said.

Production is about evenly split between the machine shop and the urethane shop, which makes injection molds and similar products. That was Proto’s bread and butter when Nay, husband Greg and partner Kurt Campbell started the company in 1995.

The couple bought out Campbell in 2002.

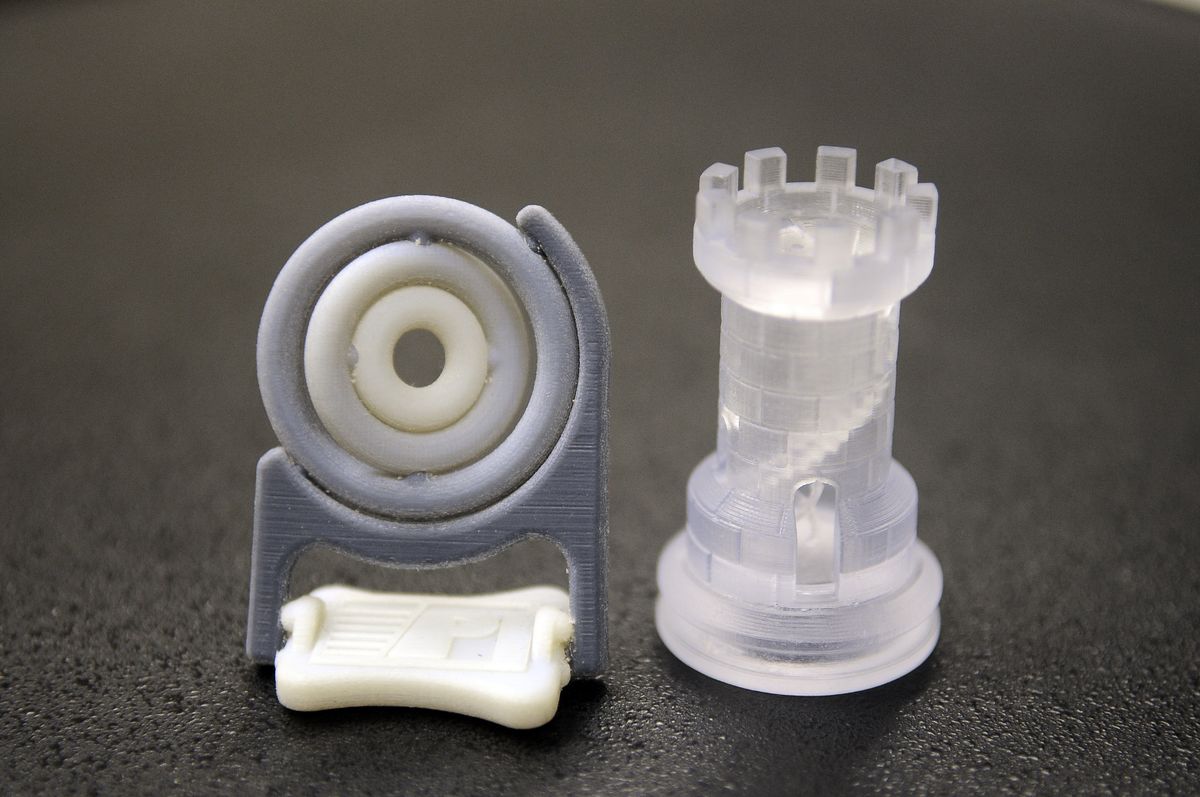

The molds start with models built using stereo-lithography, which uses lasers to fuse resins into three-dimensional forms. The newer and more sophisticated of the two machines at Proto can work with several different resins at once creating, for example, a paddle with a rigid handle but flexible blade.

The rigid models are finished by hand, which takes a level of artistry Nay said disqualifies many would-be workers.

“You have a knack for it, or you don’t,” she said.

Sometimes, Nay said, machined and molded parts are combined to give the customer a finished product.

Because the molds or machined pieces are usually one-offs or limited production, Proto rates are higher than those of volume manufacturers, Nay said.

“Our customers know when to come to us, and when not to come to us,” she said.

“We don’t want to be the biggest,” Nay said. “We just want to be the best.”