Gonzaga graduate and ‘surgineer’ helps in biotech COVID-19 solution

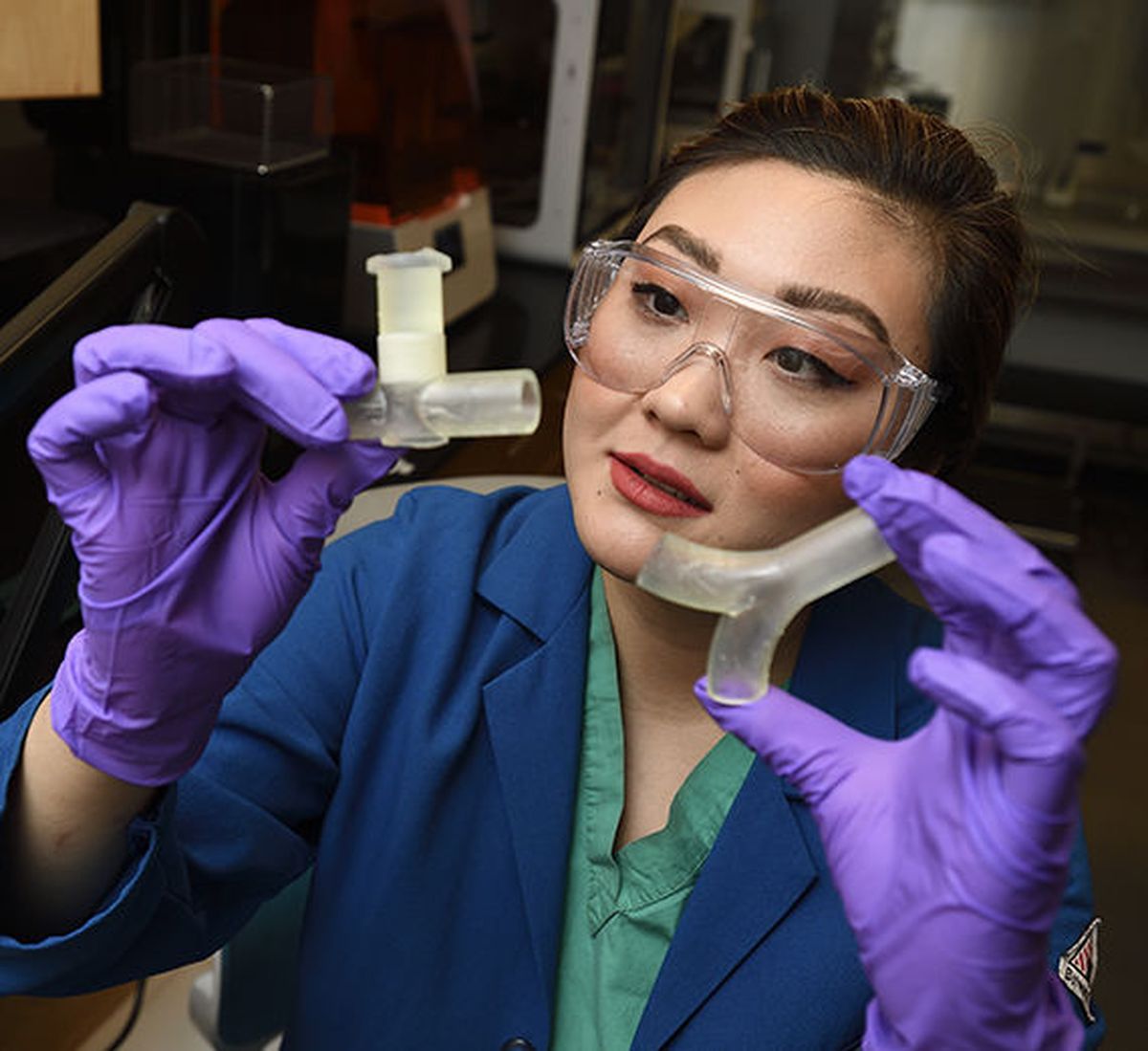

Gonzaga University biochemistry graduate Helen Xun’s work with a biotech team could help more COVID-19 patients get access to ventilators.

Xun, a medical student at Johns Hopkins School of Medicine in Baltimore, spent the 2019-20 year as a dean’s research fellow developing 3D printing technologies for rapid prototypes of medical devices with a biotech firm she co-founded.

In recent months, she and others with the biotech company developed a prototype for 3D-printed ventilator adapters, known as “splitters,” that allow one ventilator to support multiple patients with acute respiratory distress, a leading cause of death for COVID-19 patients.

Ventilator splitting is an emergency treatment that’s been used under dire circumstances, including after the 2017 Las Vegas shooting. It can be used in a crisis when there’s a surge of patients or in developing countries with equipment shortages.

“The ventilator project is essentially addressing the large ventilator shortage due to the COVID-19 pandemic,” said Xun, 27. This month, she entered her surgical rotation year at Johns Hopkins.

“When we approached this project, what we realized is you can make new ventilators, which would be the best solution, but that would take a long time and would be very expensive. We wanted to understand how we could use existing resources in the hospital.”

“In developing countries, they have baseline lack of ventilators, so when a pandemic hits, it’s more exasperated. Here in the States, it’s important for hospitals to have a good way to accommodate a surge in patients. It’s always good to have these fast options to tide the team over until more ventilators can be brought in or the patients are transported.”

The ventilator project is now pending approval by the U.S. Food and Drug Administration’s emergency use authorization that would allow the splitters to be used in certain clinical settings. Assuming FDA approval, the biotech team plans to publish its open-source design for others to use.

For developing the ventilator adapters, Xun is project coordinator. She’s working with Johns Hopkins engineering professors Sung Hoon Kang and James Guest as well as Dr. Julie Caffrey, a Johns Hopkins plastic and reconstructive surgery professor.

When they first approached the project, members knew that ventilator splitting has multiple challenges, Xun added. One challenge is ensuring that each patient has the different breathing parameters set by doctors. Another concern is the virus itself.

“There’s a virus involved, so you want to make sure that the patients next to each other on ventilators don’t infect each other again through the ventilator,” she said. “We also want to make sure that the ventilator isn’t releasing or leaking any air to potentially infect the health care providers.

“So what we’re doing is using 3D printing to make devices to add onto the ventilator so that it becomes safer to put multiple patients on one ventilator. We created a control that allows individualized breathing for each patient after they’ve been split, and we added components to reduce the risk of cross-infection. We also created a leak-free system so you don’t risk infecting health care providers.”

It’s meant to be an emergency stop-gap until more resources can be brought in, or in developing countries, for expanding the capabilities of more primitive devices to make them more ideal for COVID-19 patients.

The project went through rigorous testing, Xun said, including at a simulation center with test dummies and then it was tested on pigs at Washington University in St. Louis.

She is one of five founders of the biotech company. The collaboration began after Xun and Dr. Justin Sacks started a 3D printing lab for surgical devices when Sacks was still at Johns Hopkins. Sacks, who is still part of the biotech company, is now a plastic surgeon and chair of plastic and reconstructive surgery at Washington University School of Medicine.

The biotech work Xun has joined in is often called being a “surgineer” at Johns Hopkins, as researchers who combine surgery and engineering knowledge to find innovative ways to improve procedures, patient safety and address health care worker burnout through technologies.

With her rotation as a reconstructive surgery subinternship student, Xun will explore what it’s like to be a reconstructive surgeon before residency training. Xun said she’ll still find time to continue in the biotech company’s work.

After growing up in Portland and graduating from Sunset High School, Xun credits the time she spent at Gonzaga as leading her toward medical work. She graduated from Gonzaga in 2015.

“Thinking back to my time at Gonzaga, the Jesuit education has really contributed to my perspective on medicine – especially cura personalis and taking the philosophy and religion courses – to care for the entire person, body, mind and spirit. I think entering into the surgical world with that perspective has been really enlightening.”

Xun first entered Gonzaga as a nursing student but realized in the first year of basic science courses how much she enjoyed chemistry and biology, resulting in a switch to biochemistry.

She soon met and worked in her first research lab with Dr. Jennifer Shepherd, who encouraged Xun to pursue innovation and research. Shepherd is chair of the chemistry and biochemistry department and remembers that Xun worked with others to investigate new anti-parasitic drug targets.

“By her senior year, she was performing at the level of a second-year graduate student, ” Shepherd said in a news release about Xun’s biotech role. She wasn’t surprised to hear Xun has continued as a leader in research projects.

“Helen is a natural leader, and she will definitely make a big impact in whatever career she eventually settles on.”