Fuel for growth

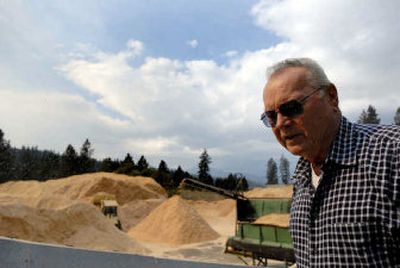

Rising natural gas prices are pumping up sales at the Atlas Pellet plant, a Coeur d’Alene company that turns sawdust into fuel.

Sawdust is dried and compressed at the plant, becoming sweet-smelling pellets burned in stoves and furnaces. The pellets sell under the names “Northwest Pride,” a mix of Douglas fir and pine sawdust, and “Atlas,” which is 100 percent fir.

Orders are running so strong that President Eric Hanson said most of his 2007 output is already spoken for. But a new plant on 10 acres in Hauser, Idaho, will help Atlas Pellet meet demand by expanding production.

Atlas Pellet had to move anyway, because its leased site on Seltice Way is being sold for development. With product sales growing, Hanson and his father and business partner, Fred Hanson, decided it was an opportune time to buy new equipment and their own piece of ground.

“Our business tracks the oil and gas markets very closely,” Eric Hanson said.

Atlas Pellet’s sales were flat in the mid- to late 1990s, when natural gas was abundant and cheap. But when energy bills rose, homeowners began looking for alternative ways to heat their houses. With prices at record highs, Americans are on track to buy 200,000 pellet stoves this year, according to Hanson. Even sales of pellet-powered barbecues are on the upswing.

“And there’s less greenhouse effect from burning a pellet appliance than your gas appliance,” Hanson said.

With its new equipment, Atlas Pellet will be able to increase its hourly output. The new plant also contains space for indoor sawdust storage, and a larger loading dock. Atlas Pellet should be in its new home by the end of November. The new plant is located on Prairie Avenue, across from Hauser Lake Lumber Co.

About $6.4 million in industrial revenue bonds will finance the move. The bonds are used to help manufacturing firms expand. Interest earned on the bonds is exempt from federal and state income tax, and as a result, the investors who buy the bonds are willing to accept a lower rate of return.

“It’s a great program,” said Hanson. “Industrial revenue bonds allow manufacturing firms to raise money at lower interest rates.”

Atlas Pellet is part of Coeur d’Alene Fiber Fuels, which also operates a plant in Omak, Wash., and is planning a third pellet plant near Olympia. About 37 people work for the company, including 20 in Coeur d’Alene.

The company started in 1986. At the time, its focus was salvaging logs from Lake Coeur d’Alene for firewood. Later, the firm contracted with the University of Idaho to provide waste wood to fuel the university’s furnaces. That was the beginning of the company’s transition to pellets, Hanson said.

Today, most of the pellets end up in the stoves of individual consumers, who buy two to four tons per year for home heating. The pellets are sold through hardware, grocery and farm and feed stores.

Atlas Pellet also sells wood shavings and a sawdust brick that competes with Pres-To-Logs.