Gasification catches on

BEULAH, N.D. — Once considered a white elephant and waste of taxpayers’ money, the Great Plains Synfuels Plant here is now hailed as pioneer of clean-coal technology. And it’s making money to boot.

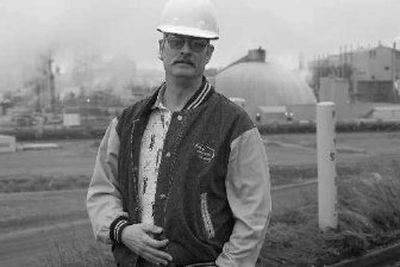

“We do have a little bit of an ‘I-told-you-so attitude’ here,” plant manager Bob Fagerstrom said. “But it’s really been a struggle to get to this point.”

After two decades of financial turmoil and fluctuating energy prices Great Plains paid its first dividends this year. While there may never be another plant like it in the U.S., energy officials say it set the stage for other types of coal-to-gas projects now on the drawing board.

The hulking industrial complex on the prairie is the only one of two in the world — the other one is in South Africa. It was built in response to the energy crisis of the 1970s to make natural gas from lignite, a low-grade coal abundant in North Dakota.

Energy officials say the plant has been used as a template for other clean coal proposals, including a process called integrated gasification combined cycle, or IGCC, for electrical generation. That process involves converting coal to a synthetic gas that is typically of a lower grade than the natural gas produced at the Beulah plant.

The gasification process at Great Plains involves using high-pressure steam and air to break down low-grade lignite coal — about 18,000 tons daily — to make natural gas that is piped to Iowa, where it is distributed to markets in the eastern and southeastern United States.

The process also generates carbon dioxide, which Great Plains pipes to oil fields in southern Saskatchewan. There, it’s pumped underground to force oil to the surface.

The plant, once considered “an anchor around our neck,” is now a darling of industry, said Ron Harper, chief executive officer of Basin Electric Cooperative, Great Plains’ owner. Engineers and scientists have traveled to North Dakota to study its carbon capture methods, and while its process has not been duplicated in other U.S. plants, it has been used to develop other clean coal technologies.

Bismarck-based Basin bought the plant from the U.S. Department of Energy in October 1988. Basin’s newly formed Dakota Gasification Co. subsidiary paid $85 million for the plant, which was built for $2.1 billion in 1984, and agreed to pass on some tax breaks and share revenues with the federal agency through 2009. Dakota Gas has paid more than $285 million in shared revenues to date.

Kurt Yeager, the former CEO of the utility industry’s Electric Power Research Institute, said while many believed the plant was a dumb idea, it is the “crown jewel” of the U.S.’s efforts to wean itself off energy from foreign sources.

“The strategic value to our country is immense and very difficult to put a price tag on,” Yeager said. “That plant and what we learned there, is a good model for what could and should be done.”

Yeager said the North Dakota gasification plant has laid the groundwork for the coal-powered plant of the future — a facility he envisions will churn out electricity and hydrogen fuel from plentiful domestic coal reserves without producing any emissions.

Many of the lessons learned at Great Plains can be applied to other plants in the future, said John Panek, an analyst for the Energy Department’s Office of Clean Energy Collaboration, who has been monitoring the plant’s operations for more than 20 years. The plant has enhanced gasification technology, and is capturing carbon, something no other coal plants are doing, he and company officials said.

“In context, this thing has been a really big stepping stone for energy,” Panek said.

Environmental groups still are still not sold on the idea. They would rather support energy conservation and renewable energy sources.

“Coal gasification is best technology when using coal,” said Wayde Schafer, a North Dakota spokesman for the Sierra Club. “But that’s like putting lipstick on a pig — you’re still using a dirty fuel source when there are cleaner alternatives available.”